Metalworking fluids are used to lubricate and cool metal machining processes such as drilling, milling and turning. The most commonly used fluids are mixed with water at high dilution rates, which means they are susceptible to bacterial contamination.

Excess bacteria in metalworking fluids can lead to respiratory disease from breathing in the mist created during machining and the subsequent washing of components.

According to the Health and Safety Executive (HSE) in Great Britain, there are normally only about 5 isolated cases of occupational asthma from metalworking fluid exposure reported to the HSE in the UK each year. However, they suspect that many cases of respiratory disease in metalworking go unrecognized. There have not been any recorded cases from exposure to water-based wash fluids used in metalworking.

The HSE has outlined guidelines for testing metalworking/cutting fluids using dipslides. We’ll get into this more next week when we sit down with Test4It Limited, but today we thought it more important to learn about the effects of bacterial contamination in cutting fluids and why it is so important to test regularly.

Outbreaks of Respiratory Disease

Generally, the causes of respiratory disease from metalworking and wash fluids are not well understood. These are complex mixtures, which change in use, and a safe level of exposure to the mist from these fluids has not yet been identified.

According to the HSE, respiratory disease from metalworking fluids has been linked to:

- The constituents of the fluids themselves, and additives

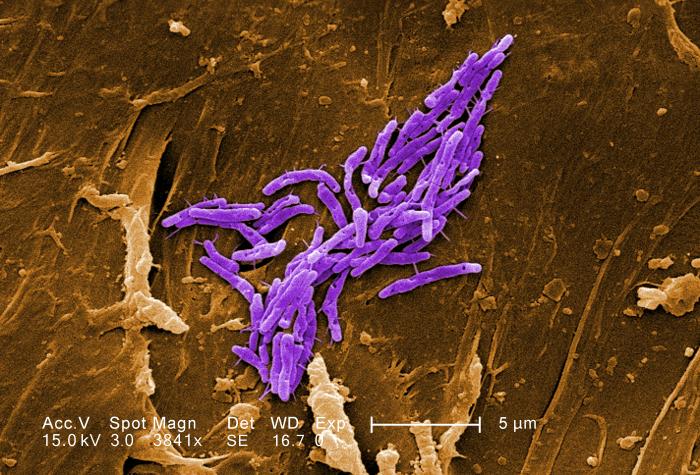

- Bacteria in the fluids (particularly mycobacteria, which are related to bacteria causing tuberculosis, but are not infectious in the same way)

- Endotoxins (released from dead bacteria, sometimes arising from biocides used to kill bacteria)

- Formaldehyde (a by-product of some biocides)

- The metals involved, such as cobalt

- Fungi in the metalworking fluids

Some of the diseases that may come from metalworking fluids include occupational asthma (OA), extrinsic allergic alveolitis (EAA) or hypersensitivity pneumonitis (HP), and work-related chronic bronchitis.

As you can see, many of these are related to bacterial/fungal contamination. This is why regular testing is so important.

Industrial Washing Machines

Figure 1: Mycobacterium fortuitum, Photo Credit: Janice Haney Carr (CDC)

Industrial washing machines are used after machining to clean components. Metalworking fluids are carried on components from metalworking machines into washing machines. Washing machines can also contain harmful microorganisms carried over with metalworking fluids on components to be washed, as well as material from the machining process, which may include sensitizing metals, such as cobalt.

Washing machines can provide a warm, moist environment, perfect for rapid spread of microorganisms. When washing machines are in use, they produce a mist from spraying fluid and high-pressure air jets, which are used to clean and dry components. It is recommended that washing fluid be tested for contamination as well.

Join us next week for our Tech Talk with Test4It Limited, where we further discuss the problems encountered with excess bacteria in metalworking/cutting fluids and what HSE Guidelines are in place for testing.

Leave A Comment