Test4it Limited provides various testing tools for the monitoring of health and safety standards within several different industries, including Health, Science, Food Safety, and Manufacturing to name a few. Test4It is based in the UK, but operates worldwide providing high quality products including test strips, test papers, detection cloths, dipslides and incubators.

Test4It has some great insight on the use of dipslides in various industries, so we asked them to fill us in on the use of dipslides in machining processes, particularly testing metalworking/cutting fluids.

Problems Encountered with Excess Bacteria in Cutting Fluids

Uncontrolled development of bacteria in metalworking fluids presents a serious risk due to the spray and mist generated by various machining processes. The cutting fluid develops aerosols when sprayed against high speed rotating work-pieces, thus presenting serious infection risks to the operators. This may be inhaled in the form of tiny droplets exposing the respiratory tract to direct infection and may also cause some skin conditions.

Other issues that arise from excess bacteria growth in cutting fluids include fouling, which leads to reduced efficiency of the actual fluid. This can result in overheating of the work-piece as well as tool damage. Excess bacteria can also affect the pH of the fluid, changing it outside the manufacturer’s specifications. And of course, there is always the unpleasant smell that arises from excess bacteria, which can be oppressive to operators in severe situations.

The above observations, although not exhaustive, make industry sectors very keen to ensure protocol is maintained at all times.

Health and Safety Executive Guidelines

The Health and Safety Executive (HSE) provides regulatory framework for work place health and safety in Great Britain. Their guidelines recommend that “direct means of monitoring bacterial contamination, such as dipslides, are essential to check the condition of fluids.”

The Health and Safety Executive (HSE) provides regulatory framework for work place health and safety in Great Britain. Their guidelines recommend that “direct means of monitoring bacterial contamination, such as dipslides, are essential to check the condition of fluids.”

Weekly testing with the Nutrient-TTC / Malt Dipslide is recommended. This allows for simple screening of fluids to establish the level of bacteria and decide appropriate action or monitor the performance/dose level of any biocide treatment regime.

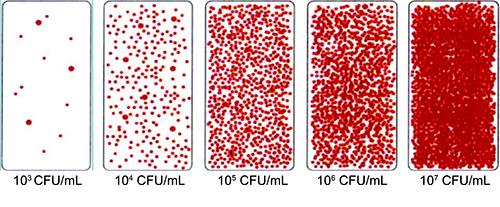

The Nutrient-TTC agar will give a clear bacteria count, since coliform bacteria grow as red dots. The Malt agar provides a clear fungal count.

Incubation is important to promote accurate culture growth. The dipslide is best incubated at 30°C – bacteria will need at least 48 hours for counts, and fungal counts can take up to 5 days. Incubation at 35°C will promote a more rapid bacteria count, but may be detrimental to fungal counts as they tend to prefer cooler, damp conditions. If facilities allow, 32-33°C is a happy medium, although it’s worth continuing incubation for up to 72 hours for bacteria, especially if counts initially appear low.

According to the HSE, results are expressed in terms of colony-forming units per milliliter of fluid (cfu/ml). Less than 103 cfu/ml are considered to indicate good control of bacteria; between 103 – 106 cfu/ml indicates reasonable control, and greater than 106 cfu/ml indicates poor control. Bacteria counts exceeding 103 requires action in the form of a Biocide or cleaning regime review.

To learn more about the problems that can arise from excess bacterial contamination in cutting fluids and HSE guidelines, read this report from HSE. It outlines emerging lessons for suppliers and users of metalworking wash and fluids, health professionals, and designers of metalworking and washing machines.

To learn more about the problems that can arise from excess bacterial contamination in cutting fluids and HSE guidelines, read this report from HSE. It outlines emerging lessons for suppliers and users of metalworking wash and fluids, health professionals, and designers of metalworking and washing machines.

A special thanks to Robin Offord of Test4It Limited for providing all of the information above.

Leave A Comment