You can gather a bit of our company history from the About Us page on our website, but what you won’t find there are some of the entertaining stories we hear our CEO, Howard Kimel, share of his earlier days at Precision. Stories about how things were “back in the day,” that familiar phrase we all know so well. A time when you had to walk eight miles to school through two feet of snow.

In this case, the stories from Howard’s early days at Precision, back when the company resided in Cincinnati, give our history some colorful character. A few employees that worked at Precision “back in the day” have found our website, reached out to us, and shared some of their stories from their time at Precision. Coupled with Howard’s tales, it paints a pretty vivid picture of how our company started. It’s one of those garage start-up stories. Literally.

Precision started out as a family business in 1932, the brilliant idea of one, John Tucker. Tucker was not the only one in this time period with the foresight to start up a test strip company. A few others did the same, and some of them are also still around today. However, the litmus paper Tucker was making was pretty unique to Precision.

The company began in Tucker’s garage in Deer Park, Ohio. Precision’s first and primary products were litmus paper, still a staple of our business today. Back then, we can’t speculate as to how the smaller batches of litmus were initially made, but we’re betting it was a pretty crude method (you’ll see why in a minute).

Eventually, as the company began to grow, they moved to a location on Reading Road in Cincinnati. At the time, Precision was one of two companies in the world supplying litmus paper. You can imagine why it took off so quickly.

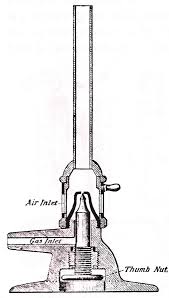

Once the company had grown to a larger scale, the litmus was cooked in a 55 gallon trash can set up on a couple of cinderblocks over a meker burner (see, pretty crude). It was cooked this way for at least 12 hours, then left to cool and settle. The liquid was then decanted from the pot and used to treat sheets of paper.

Once the company had grown to a larger scale, the litmus was cooked in a 55 gallon trash can set up on a couple of cinderblocks over a meker burner (see, pretty crude). It was cooked this way for at least 12 hours, then left to cool and settle. The liquid was then decanted from the pot and used to treat sheets of paper.

The treated sheets were hung on hooks until they dried. One former employee recalls “standing for hours hanging 3’x3’ sheets of filter paper” that had been dipped into the litmus solution. Once dry, the sheets were removed from the hooks, counted, separated, and cut into strips on a hydraulic paper cutter.

This particular employee remembered following the same procedures for other test papers (as the product line began to expand), however, these other papers were alcohol-based instead of water-based. He recalls, “The solution would soak through my skin. As a result, my hands were all sorts of colors when I made the test papers. As the hooks that held the soaked test papers were very sharp and the papers were so thin, I could not wear gloves when I hung them.” The phrase, “the good ‘ol days,” doesn’t come to mind here.

John Tucker was a good judge of character, a thoughtful person, and a smart business man. He enjoyed his work and tried to make some monotonous tasks more enjoyable for his employees as well. He used to have competitions with his employees to see who could hang paper and finish hanging the “hook room” the fastest with the fewest mistakes.

Eventually, John put the business up for sale so he could retire. At the time, Howard was running his own business, Kimtech Educational Company in Washington D.C. A purchasing agent from a company called Science Kit, who also sold into the educational marketplace like Howard, told him about the litmus paper company for sale in Cincinnati. So, Howard went and met with John.

Howard doesn’t know why John Tucker chose him to take over the business, but John obviously saw something in him. Tucker took a leap of faith with Howard when it came to selling the business. Howard did not have enough money to buy, and it seemed Tucker was already giving him a great deal on the business.

Howard recalls thinking, “What do I need another business for?” Regardless, he consulted with his accountant about Tucker’s business. His accountant immediately and strongly recommended Howard pursue the opportunity and purchase the business.

As Howard puts it, “he fooled around for some time” before John came back to him asking Howard to make him an offer. Howard had very little money saved up, so he paid a visit to the president of his bank. After meeting with the bank president, he told Howard to buy the company. In fact, he even offered to loan Howard much of the down payment to purchase the company. Howard is no fool, and he knew his banker and accountant must see something in the company, some potential or growth opportunity.

John had asked Howard for $375,000 to be paid off over a five year period, in quarterly installments, with a $100,000 down payment. At the time, John was doing about $300,000 a year in sales. Howard borrowed most of the down payment from his banker, and the rest is history. He purchased Precision Laboratories on July 1, 1986.

In the late 90’s, Howard and his wife took a trip to the West coast. During their trip, they drove through Oak Creek Canyon in Sedona, which is a beautiful drive for those of you unaware. They stopped at an ice cream shop for a quick treat, and saw a real estate office across the street. Curious about houses in this beautiful town, they stopped in, met with a realtor, and bought a house in Sedona the same day.

In the late 90’s, Howard and his wife took a trip to the West coast. During their trip, they drove through Oak Creek Canyon in Sedona, which is a beautiful drive for those of you unaware. They stopped at an ice cream shop for a quick treat, and saw a real estate office across the street. Curious about houses in this beautiful town, they stopped in, met with a realtor, and bought a house in Sedona the same day.

After commuting back and forth from Cincinnati to Sedona for a little while, Howard eventually moved Precision to Cottonwood, Arizona in 2003. We are still in the same building today, although a few additions have been made. As it turned out, the dry heat in Arizona is incredibly helpful in drying the treated papers, and it cut production time down significantly. Who knew an ice cream cone would lead to such a smart business decision?

Howard has continuously grown the business since taking over. During his travels in the Czech Republic one year, he met Dr. Eva Hrboticka, an incredibly intelligent and talented chemist at the largest pharmaceutical company in Czech Republic. After having tea and cookies a couple of times, Howard had a strong gut feeling about Dr. Hrboticka, and asked her if she would work for Precision. They agreed on a handshake that has now lasted 14 years.

Dr. Hrboticka has been instrumental in test strip development for Precision, and many of the strips we manufacture today are a product of her research and development. She maintains a lab in the Czech Republic and continues to do R&D work with the assistance of her daughter and son-in-law, both of whom she has diligently trained on each product she has developed.

During travels to the United Kingdom, Howard has made several contacts in the industry, which eventually led to purchasing part of Casp in 2010, a dipslide manufacturing company; opening our Precision Europe office in 2012; and investing in Lynd Products, a portable incubator manufacturer, in 2015.

This was a long-winded and in-depth look at some of the quirks in our company history, but we feel it’s important because our history is a part of who we are as a company today. We still operate like a family-run business, and although improved upon, we operate with many processes similar to what John Tucker first did. If you watch the manufacturing videos on our website, you’ll see the “hanging room” with all the hooks where our paper is dried. You’ll see the large hydraulic cutters used to cut the paper sheets into strips. You’ll see us occasionally having a bit of fun doing some of the monotonous tasks involved in manufacturing test strips. But ultimately, we’re a close-knit group of people, continually trying to please our customers, maintain the quality that goes hand-in-hand with Precision’s name, and grow the business further as John Tucker first saw possible.

like a family-run business, and although improved upon, we operate with many processes similar to what John Tucker first did. If you watch the manufacturing videos on our website, you’ll see the “hanging room” with all the hooks where our paper is dried. You’ll see the large hydraulic cutters used to cut the paper sheets into strips. You’ll see us occasionally having a bit of fun doing some of the monotonous tasks involved in manufacturing test strips. But ultimately, we’re a close-knit group of people, continually trying to please our customers, maintain the quality that goes hand-in-hand with Precision’s name, and grow the business further as John Tucker first saw possible.

Leave A Comment