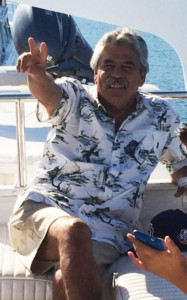

Meet Manny Duarte, the man behind the start of it all. Manny is responsible for the first steps in making our test strips. He makes some of the chemical solutions used to treat the paper, and sometimes uses solutions already made up by Scott. He then takes those solutions, and pours them into a large shallow bin on a rolling cart in the hanging room.

Meet Manny Duarte, the man behind the start of it all. Manny is responsible for the first steps in making our test strips. He makes some of the chemical solutions used to treat the paper, and sometimes uses solutions already made up by Scott. He then takes those solutions, and pours them into a large shallow bin on a rolling cart in the hanging room.

The hanging room is where we hang our wet, treated paper on hooks to dry. The paper starts out as a large sheet, usually 20” x 26”. Manny dips each sheet of paper into the solution, then hangs it on the hooks to dry. Depending on the paper and the solution, sometimes he has to wax the corners of the paper first, to ensure it doesn’t tear off the hooks under the weight of the solution.

He moves the cart down the rows of hooks, hanging each treated sheet one by one. He has to dip each sheet carefully to ensure it’s fully and evenly coated in the solution. Depending on the solution being used, he may also have to take extra precautions, like wearing a protective mask for solutions with a high alcohol content, or work in a low, dim light for light sensitive papers.

And eventually, when the papers are dry, he walks down the rows of hooks pulling the sheets off and counting them, stacking them, and pressing them under heavy weights to remove all the extra “fluff”.

Manny is dedicated to this job, and he works all hours of the day to make sure the paper is ready when the rest of the production crew arrives. He is also extremely efficient and fluent at his job. He has been doing it for years. He is a very reliable and dependable member of the team, and his role is crucial in the process.

Leave A Comment